IT'S NATIONAL 811 DAY!

Today is National 811 Day – we are reminded to call 811 (or visit call811.com) before digging – in our yards or at a construction site. This simple reminder has saved lives and repair costs by preventing accidental damage to power lines, gas lines and other buried utilities during excavation.

A Blog by Emily Pierce, PLS, CFedS

“Notification NOT Made” was the single greatest root cause, selected for 23% of damages submitted. Although we continue to make progress, this root cause has hovered around 25% for the past six years.

“Notification NOT Made” was the single greatest root cause, selected for 23% of damages submitted. Although we continue to make progress, this root cause has hovered around 25% for the past six years.

Today is National 811 Day – we are reminded to call 811 (or visit call811.com) before digging – in our yards or at a construction site. This simple reminder has saved lives and repair costs by preventing accidental damage to power lines, gas lines and other buried utilities during excavation.

While we know that 811 has some inefficiencies, it is the best first line of defense for damage prevention for a property owner and the utility. Without proper locating subsurface utilities before excavation, the results can be costly.

Unfortunately, according to the latest DIRT Report (Damage Information Reporting Tool), the most frequent root cause of excavation damage was “failure to notify the one call center.” This cause of excavation damage is the most preventable. It’s also free for the reporter, so it’s also the most cost effective.

The cost estimate of not making the call to 811 is just that – an estimate. The United States lacks a requirement to report excavation incidents, so no one really has the data. Likewise, most states have a one-call center that’s funded and run by the utility partners themselves. Tracking excavation incidents across the board may not be compiled completely, or done on an individual utility company basis and not shared publicly. However, the Common Ground Alliance (CGA) has a reporting system that incorporates both voluntary and required submissions that offers a look into the root cause excavation damages.

It’s interesting to have a look at what it costs not to locate underground utilities.

According to a recent white paper by Geoff Zeiss and Dr. Sakuran Shinoaki, the cost (direct and indirect) of utility damage in the U.S. is $50-100 billion annually. The range is so broad because we don’t have a required or comprehensive reporting system. We actually don’t know how many excavating accidents happen and what they cost.

The paper goes on to present examples of utilities using mapping / modeling technologies to accurately model underground infrastructure. Recent advances in technology mean that ground penetrating radar and LiDAR can be used by surveyors to effectively capture underground infrastructure. When combined with GIS and other emerging technologies, accurate images of buried utilities could save billions of dollars annually and prevent loss of life.

Why isn’t more being done to accurately map buried infrastructure?

“IT HAS BEEN ARGUED THAT LIABILITIES MAY BE THE SINGLE MOST IMPORTANT KEY TO IMPROVING THE QUALITY OF LOCATION INFORMATION ABOUT UNDERGROUND INFRASTRUCTURE.”

The most interesting paragraph in this paper points to the reason why no coordinated effort exists to create an accurate and comprehensive reporting system. “It has been argued that liabilities may be the single most important key to improving the quality of location information about underground infrastructure.” I assume this means that if accurate information exists, then it might actually increase the financial risk of those involved in an excavation accident. This is disheartening as the cost paid isn’t always financial. There have been lives lost and injuries sustained, which carries a bigger burden than just money.

However, there is hope, as “some jurisdictions are implementing policies for shared liabilities to motivate all stakeholders to become involved in capturing and sharing better data about underground infrastructure to reduce risk.”

Additionally, I’ve spent the last few years lobbying on Capitol Hill with other members of the National Society of Professional Surveyors (NSPS) for the importance of accurate geospatial data for infrastructure projects. NSPS has taken a very active role with the importance of accurate geospatial data to be required for all infrastructure projects, including the physical framework of transportation, energy, communications, water supply, and other systems.

Opportunity for surveyors

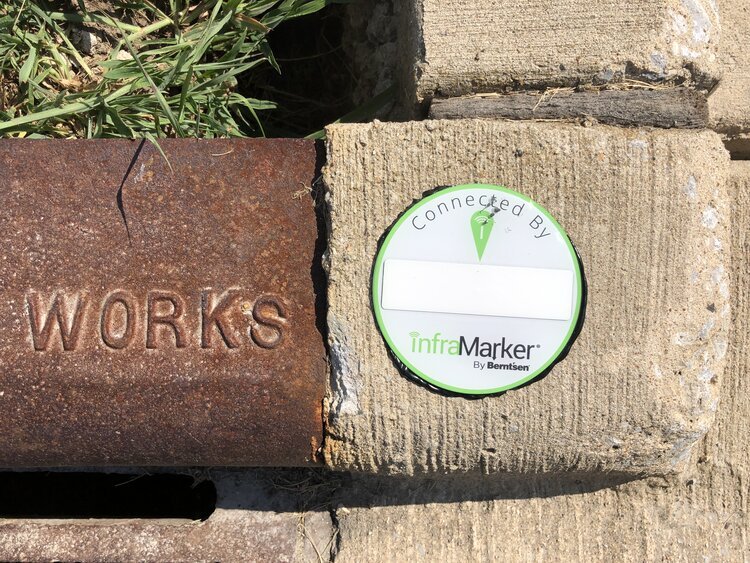

Fortunately, industry-wide, there is a trend toward acknowledging the need for accurate underground infrastructure data and organizations are adopting new technologies to conduct underground surveys. A number of organizations are encouraging surveyors to become qualified in these new technologies and learn how to apply them in underground surveys. Along with GIS, LiDAR and GPR, other tools are making the job of underground surveying much easier. For example, an existing technology is now being used to tie physical assets to the data in GIS. For the past decade, Berntsen has been developing RFID to work with existing GIS platforms. The InfraMarker RFID solution is now being used to mark assets in the field and tie that specific location to the asset record in GIS. That means that with a simple RFID scan, a surveyor or field technician can identify each specific asset and access its record in the field, update the information and have that data instantly available in the GIS, accessible for locating, tracking, maintenance scheduling, planning and more.

So what needs to change?

Well, I think we all have a hand to play.

First, property owners have the responsibility to call 811. This ensures that first line of defense and reduces their risk of liability if something is damaged.

Then, utility locators have the responsibility to find ways to improve the speed and accuracy of locating. This likely includes increasing staff and resources so that the right people are available for quick marking turnaround.

Additionally, utility owners have the responsibility to invest in safety practices and technology that increases the accuracy of asset mapping/locating. This is an important step especially during the installation of new underground utilities. Accurate marking and mapping will protect infrastructure investments in the future. Surveyors are the key component to providing that accurate information to utilities.

It’s 811, and a great day to be a surveyor! We have the opportunity to make the world a better and safer place. I’m looking forward to helping the world “know what’s below.”

INSTALLATION PREPARATION

InfraMarker uses a 3-level approach for geo-data management. Data added to the tag stores information related to the asset, including the tag position relative to the asset.

Field data collection verifies the tag’s position relative to other above-ground assets (such as a photo of asset [or the asset revealed by excavation], or videos of the surrounding terrain to assist in relocating the asset) and can include comments related to the installation or reading of that tag.

Equipment and preparation needed to install, locate, and map InfraMarker®

InfraMarker uses a 3-level approach for geo-data management. Data added to the tag stores information related to the asset, including the tag position relative to the asset.

Field data collection verifies the tag’s position relative to other above-ground assets (such as a photo of asset [or the asset revealed by excavation], or videos of the surrounding terrain to assist in relocating the asset) and can include comments related to the installation or reading of that tag.

Data added by the administrator is appended to the record and may include customer specific information, historical records or other documents related to that asset.

INFRAMARKER TAGS

InfraMarker tags are standard Class 1, Gen 2 RFID tags that have been tested and approved by InfraMarker for use in infrastructure management applications. The InfraMarker tags are provided to the customer with a standard data schema that works with InfraMarker software.

The standard data schema is set up as follows:

Asset Owner

Asset Type

Asset Function

Asset Material

Asset Feature

Latitude

Longitude

Tag Install Date/Time stamp

Depth from Surface to Asset

Offset Direction & Distance

TWO TYPES OF INFRAMARKER TAGS ARE AVAILABLE

InfraMarker-enabled underground markers that include an RFID tag, magnet, and steel backing. These tags are the IM483B, IM362B, IM221B , and IMDEEP 1.

InfraMarker-enabled above ground marking products including customizeable label for catch basin, curb marking or other applications where a label is required. In addition, the fire hydrant marker is available and can be used on metal hydrants or utility poles.

APP DATA RECORD

The InfraMarker record is contained in the app and uploaded to your GIS or the InfraMarker Cloud in the following format:

Tag information

Handheld data information

Mobile Device ID

User ID from Mobile Device

Date/Time Stamp of read

Comments [recommended to communicate information about the tag position relative to other landmarks or important information related to above ground location].

CLOUD RECORD

Every app record from every InfraMarker tag is uploaded to your GIS system or the InfraMarker cloud. This record can be appended by the customer with information specific their asset management needs.

INFRAMARKER WEBSITE

The InfraMarker website collects registration information, controls user access for download and display, links to InfraMarker training and support material, and offers the customer the ability to purchase InfraMarker related marking products and support.

RFID SCANNER

InfraMarker’s lightweight Bluetooth® UHF RFID readers are capable of reading and writing to tags directly from a Bluetooth-enabled mobile device. Equipped with a powerful Impinj R2000 core and range of interchangeable high-performance antennas, it delivers reliable reads even in difficult or deep placements.